KING OF PRUSSIA, PA., July 23, 2024 – OrthoSpineNews – Camber Backbone, a number one innovator in spine and medical applied sciences, introduced at present that it has obtained U.S. Food and Drug Administration (FDA) 510(ok) clearance for its SPIRA-A Built-in expertise.

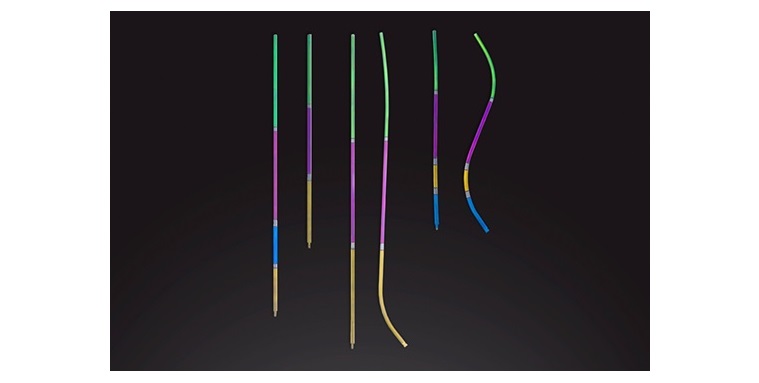

A part of the SPIRA product platform, the SPIRA-A Built-in Fixation System is an anterior lumbar interbody fusion system that has an open matrix design to allow packing with autogenous and/or allogenous graft materials to facilitate fusion in addition to further fixation choices to safe the implant within the disc area.

“The FDA’s 510(ok) clearance of our SPIRA-A Built-in expertise ushers within the subsequent evolution in our revolutionary SPIRA platform and marks one other main step ahead in our firm’s growth,” stated Camber Backbone CEO Brooks McAdam. “It additionally helps carry extra innovation-based options and choices to the surgical group and an answer for surgeons participating or wanting to have interaction within the ALIF market. We imagine SPIRA Know-how, which encompasses the construction, floor, and science behind our 3D-printing course of, is the archetypal design for contemporary spine implants and exemplifies the true advantages of additive manufacturing.”

SPIRA-A Built-in presents an entire answer to the ALIF process, with built-in fixation deployed in a conventional ALIF cage and strategy in addition to a windswept cage geometry for accessing L5-S1 with troublesome vascular anatomy, and every implant presents as much as 40 factors of endplate contact.

The superior and inferior surfaces of the SPIRA-A Built-in system have a tough floor to assist forestall motion of the system whereas fusion takes place, and structural arches to assist distribute load throughout the joint area. The system accommodates three holes to insert bone screws or anchors for built-in fixation, in addition to blocking screws to stop fixation back-out.

SPIRA-A’s screws and anchors have been designed to enhance the efficiency of the cage, enhance fixation within the cortical endplate, and supply first-of-their-kind 3D-printed anchors with a SPIRA Floor, designed to extend potential for osseointegration and resist pull-out.

The strong inserter attachment, a number of method potentialities, and all kinds of screw prep choices are designed to facilitate clear visualization of, and quick access to, the surgical website as soon as the strategy is full.

The FDA’s motion implies that SPIRA-A Built-in is now indicated to be used at a number of ranges from L1-S1 as an adjunct to fusion in skeletally mature sufferers with degenerative disc illness (DDD), disc herniation (with myelopathy and/or radiculopathy) spondylolisthesis, deformity (degenerative scoliosis or kyphosis), spinal stenosis and failed earlier fusion (pseudarthrosis).

Camber’s SPIRA implants are 3D printed. This specialised manufacturing expertise permits Camber to create distinctive patented constructions that includes open arched matrices and proprietary surfaces designed to boost fusion and promote bone development.

All of Camber Backbone’s merchandise are developed and manufactured in the USA.

###

Progressive spine and medical expertise firm Camber Backbone Applied sciences is devoted to creating surgeon-designed options in MIS and minimally disruptive entry for the remedy of advanced spinal pathology. Incorporating state-of-the-art manufacturing, 3-D printing, and an acute sensitivity to affected person anatomy, Camber Backbone is making quantum leaps within the spinal fusion market. Be taught extra at CamberMedtech.com.

Media Contact: Paul Williams, 310-569-0023, paul@medialinecommunications.com

Discussion about this post